Demand Planning & Forecasting

Post on: 29 Август, 2015 No Comment

What is demand planning and forecasting?

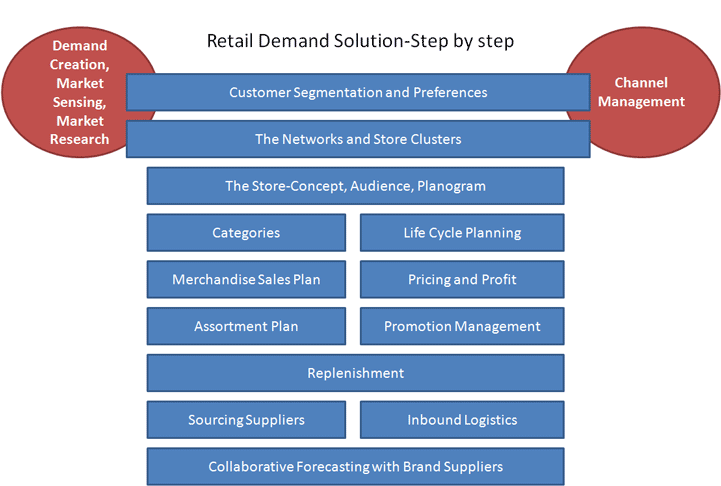

Demand planning and forecasting is a business process that involves predicting future demand for products and services and aligning production and distribution capabilities accordingly. It involves a number of different business functions and requires the sharing of timely data, accurate processing of this data and agreement on joint business plans along the supply chain.

The process consists of three parts:

- Demand forecasting: The creation of a projection for unconstrained demand for a product or service over time

- Demand planning: The development of a forecast that reflects known constraints and any possible associated impacts that may occur as a result of external events, capacity (either production or logistics) or changing priorities

- Demand management: Influencing demand via the addition (or cancellation) of activity, the increasing or reduction of price, or the rationing or allocation of stock

Increased investment in forecasting

Greater competition, more frequent new product launches and shorter product life cycles have made forecasting increasingly complex.

Organisations themselves have also become more complex in the past decade, and many now operate in a greater number of locations, business units and markets. Unprecedented levels of economic uncertainty, which have affected buying patterns and historical data, have added to this complexity.

Our research highlights that the need to improve service levels and reduce stockholding are the two biggest drivers to investment of resources in the forecasting and demand planning process.

Key demand planning challenges

According to our research, there are three main obstacles facing the industry in the area of forecast accuracy performance, as follows:

- Poor communication, for example the late communication of changes in promotional mechanics

- Insufficient internal collaboration and inadequate processes to manage business and customer requirements

- A knowledge gap caused by issues such as a lack of a recognised forecasting tool or process, promotional complexity and data integrity

In addition to these challenges, there are organisational issues. For example, within an organisation, who is responsible for a forecast, and is that person also accountable for it? If not, is this individual empowered to influence or challenge the forecast?

The forecast cycle

IGD research highlights that a typical short-term forecasting cycle includes the following steps:

20forecast%20cycle.jpg /%

Measuring forecast accuracy

The key to good forecasting is consistent accuracy, as this will help companies set correct inventory levels, avoiding over-stocks and out-of-stocks. Where forecasts are consistently higher than actual sales, inventory levels will rise. Where they are consistently lower, issues with service levels will become more frequent.

Forecast accuracy can be measured at multiple levels, including at product, customer or business level.

Benefits of measuring forecast accuracy

The need to improve service and reduce stockholding has driven businesses to invest resources in the forecasting and demand planning process.

IGD research has identified a number of key benefits to measuring forecast accuracy –

- Service benefits – in addition to having a clear impact on customer service, a formal demand planning process helps companies to respond quicker to market-related developments

- Cost benefits – these include lower waste, improved production accuracy, reduced stock holding and better capacity planning

- Revenue benefits – through stronger availability on-shelf, and being closer to the business plan

- Organisational benefits – such as better accountability, greater control over processes, a reduced level of ambiguity and improved internal collaboration

Measurement calculations

Absolute Forecast Accuracy

Forecast Bias

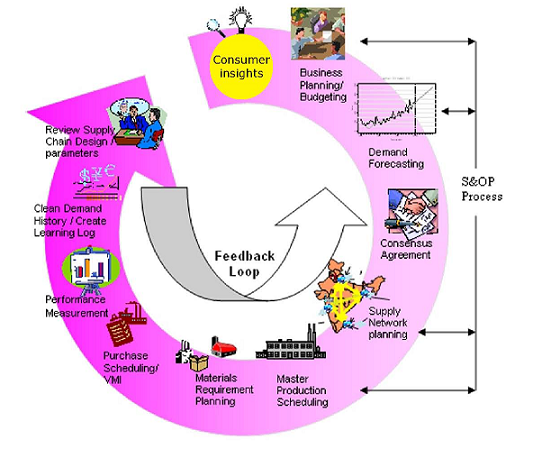

Collaboration is key

A lack of collaboration with trading partners is seen as a key frustration for suppliers in the demand planning process. It indicates that despite efforts to share information, this is not common practice across the industry, and is not sufficient on its own.

The way forward

Flexibility in responsiveness and the robustness of integrated business planning are important factors in delivering real-time, demand-led supply chains, but companies need to take a more systematic approach to demand planning and forecasting. There is a need to strive for deeper collaborative supply chain practices, both within organisations and with trading partners. As such, developing collaborative supply chain practices will drive business capability, optimise service levels, reduce wastage and maximise on-shelf availability.

Free download — Promotions and availability — five points to consider

In this complimentary whitepaper from IGD Supply Chain Analysis, we reveal what retailers and manufacturers think are the main barriers to achieving good on-shelf availability with promotions. We look at five key areas you should focus on when trying to ensure your products on promotion are available in-store.

To download ‘Promotions and availability — five points to consider’ simply click on the link below and complete your details.

Want to better understand supply, demand and strategy planning?

Covering big themes including supply chain collaboration, forecasting and demand planning, the Strategy and planning hub on IGD Supply Chain Analysis brings together the latest news, downloadable presentations and industry case studies to help you tailor your strategy with key customers.