The Changing Iron Ore Industry The Freeman Foundation for Economic Education

Post on: 16 Март, 2015 No Comment

Mr. Lloyd is Administrative Vice-President, International and Raw MaterialsStaff, United States Steel Corporation. This article is condensed from a paper presented at the Pittsburgh Regional Technical Meeting of the American Iron and Steel Institute, November 16, 1960.

Historically, steel producing centers have always been located with reference to the accessibility of raw materialsiron ore, coal, and limestone. This was the case in Britain, in Alsace-Lorraine, in Birmingham, and Pittsburgh. In recent years, however, other considerations such as market potentials and even national politics have become of increasing importance in determining the location of new steel plants. This fact is evidenced by the number of small steel mills that are springing up in Latin America; the growth of the Japanese steel industry, sustained to a large extent on imported raw materials; and the geographical dispersion of steel mills within the United States and Europe to take advantage of local markets.

In the past, leading steel producing nations have generally also been leading iron ore producing nations. Actually, the importation of large tonnages of iron ore into major production centers is relatively new in the long history of steelmaking. Only in recent years have improved handling and transportation methods, rising ore prices and labor costs, and the consequent values of the iron producing potentials of higher quality ores in certain market situations made it possible for imported ore, in many instances, to compete with domestic ore in meeting part of the over-all steel demand.

Before World War II, few people would have believed that some day iron ore would move from Nevada to Japan, from India to Western Europe, and even from Chile to Lower Lakes ports, such as Detroit.

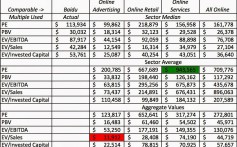

Most of the export ore flows to four large markets, the United States, Great Britain, the six nations of the European Coal and Steel Community, and Japan. However, it should not be considered that the marketing pattern is fixed. On the contrary, it is continually changing as consumption demands shift from one geographic center to another as ocean freight rates fluctuate, as new ore deposits are discovered and equipped for production, and as currency controls and exchange regulations affect purchases. Note the complex crisscrossing of the trade routes. At first sight some of these seem illogical, but in every case there is a reason behind the movement, a price-quality ratio that makes that particular ore attractive today in that particular market. Tomorrow, any of the factors I have just mentioned may destroy an attractive price-quality ratio and that particular ore will then cease to flow.

Shifting Markets

The rapid increase in the use of imported iron ores throughout the world after World War II, and particularly since 1952, can be attributed to a number of phenomena, which differ from country to country. In the case of Great Britain and Japan, the reason is the substantial growth in steel capacity which outstripped the economics of domestic ore reserves; in the case

%img src=file:///C:/DOCUME

1/snjoroge/LOCALS

1/Temp/msohtml1/01/clip_image002.jpg /%

%img src=file:///C:/DOCUME

1/snjoroge/LOCALS

1/Temp/msohtml1/01/clip_image004.jpg /%

Principal iron ore resources of the world. 1958.

of the United States, the building of new steelmaking facilities to service market areas more remote from domestic ore sources, but easily accessible to imported ores, plus the furnace benefits realizable at some plants from the generally higher quality foreign ores; in Western Europe, the rapid postwar expansion of steel capacity which would have required large uneconomic investments in mining facilities if only domestic ores were utilized; and in general, the availability of low cost ocean transportation as a result of larger, specially designed ore carriers and more efficient dock and ore handling facilities. These and others are the reasons generally expressed. In every case, however, the basic underlying reason for the increase in iron ore imports of which all these things are a part is that the price-quality ratios of the iron ores in demand at these particular times and places are more attractive than the price-quality ratios of the available domestic ores.

Cost Factors

There are three important factors that can influence the price part of the price-quality ratio, namely, mining costs, transportation costs and artificial trade restrictions.

Mining costs are an important item in the over-all delivered cost of every iron ore. They are determined largely by mining plant efficiency, labor costs, and tax costs. Although reasons may vary from case to case, it is generally true that the iron ore exporting countries enjoy relatively lower mining costs, in terms of cents per unit of contained iron, than do the importing countries. In some cases, such as Canada and Venezuela, low costs are in a large degree attributable to the investments made in modern and efficient plants. In India and Brazil, low

Millions of Metric Tons costs involve the high quality of the ore, in addition to relatively high labor productivity in terms of wage costs per unit. Tax costs are important items in total mining costs, whether they are local or national. Unfortunately, they are not readily controllable by the producer.

Another important iron ore cost item is transportation. The capital investment involved in producing low cost ocean transportation is substantial and can only be justified if depreciable over a considerable annual tonnage. Therefore, export trade will, over the years, tend to become concentrated in large operations that can support such capital investments.

The third important influence in determining price and the pattern of trade in the international market is the factor of artificial trade restrictions, such as quotas and tariffs. Many nations or groups of nations have used in the past, and still use, these trade restrictions as a means of enabling domestic industrial production to maintain its position in the home market in the face of available imports. Iron ore, however, has traditionally moved freely in the market; and fortunately, no tariffs or quotas have ever been imposed anywhere to limit this freedom. Certainly no restrictive move would appear to be worth-while in the case of iron ore. As an example, let us take a minute to see just what would happen if a country were to attempt to restrict the flow of iron ore by setting up tariffs. To the extent that the tariff is high enough to keep out foreign oresand it would have to be quite high to make domestic ores competitive in widely dispersed steelmaking centersthe labor involved in mining, processing, and transporting the ore from mine to consuming plant would be shifted from foreign to domestic hands; and taxes assessable on profits realized on these operations would be shifted to a greater or lesser extent from foreign taxing authorities to domestic taxing authorities. On first thought this shift might appear to be all to the good as far as the domestic economy is concerned.

Unseen Consequences

However, looking further into the matter, it becomes evident that to the extent that the price of the substitute domestic ore delivered to the steelmaker would then exceed the price of the replaced foreign ore, by just that amount is the cost of steel increased; and this increased steel cost would in turn be ultimately reflected in increased costs of steel products. Certainly the major results would be:

Decreased exports of steel products which at the higher costs, and hence prices, find themselves no longer competitive in the foreign market;

Increased imports of steel products from foreign sources that have now acquired a new competitive advantage; and

As a consequence of 1 and 2, decreased domestic production of steel and steel products.

Inasmuch as approximately 11/2 tons of iron ore are used for every ton of finished steel, and it requires 30 times more man hours to produce a ton of finished steel than to produce a ton of ore, any temporary increase in domestic iron mining employment brought about by the substitution of lower price-quality ratio domestic ores for higher price-quality ratio foreign ores would be offset many times over by the resultant reduction in employment in steel production and transportation of steel products, to say nothing of the loss of employment in the related raw materials mining and transporting industries such as coal, limestone, and scrap. However, this is not all, for as steel production might be curtailed, the demand for iron ore would fall off so that the apparent tariff-generated increase of jobs in the domestic ore mining industry would prove to be only temporary and actually more illusory than real.

The Tax Picture

A similar situation develops with respect to federal and even to state tax revenues. Increased federal taxes that might be collected from the domestic iron mining industry with iron ore import restrictions could be offset many-fold by decreased collections from the steel industry and the other industries serving it, as well as from the manufacturers of products made from steel. Eventually decreased state tax revenues would also be inevitable.

In short, while tariffs or other restrictions on iron ore imports might temporarily benefit some iron ore mining communities, both labor-wise and tax-wise, the nation as a wholelabor, the tax coffers, and the consuming publicwould be heavy losers.

For economic reasons, as well as from the point of view of long term supply, a continued free and unrestricted flow of iron ore throughout the world is essential to the best interests of the iron ore industry, of the steel industry, and of the public at large. This is true for individual nations and for the free world as a whole.

We as a nation must permit the natural law of supply and demand to operate unhampered by artificial restrictions if our steel using industries, our raw material producers, our labor force, and our nation as a whole are to prosper.

***

Government in Industry

And even in cases where a government may go so far as to start an industrial enterprise, I think every effort should be made to put the venture into the hands of private capital and private management as quickly as possible.

For rare exceptions do not disprove the often illustrated rule that it is not in the nature of government to act with the flexibility or the attention to business considerations that is required of good industrial management. Andsuccessful or notso long as the enterprise stays in government hands, it does not stimulate the growth of similar enterprises, because private investors who could finance them are not willing to try to compete with government. The net result of these state ventures, more often than not, is to restrict the growth of productionor in other words, to defeat the very purpose they seek.

Eugene R. Black, President of the World Bank, in Istanbul, November 1955