PITFALLS OF NEW TECHNOLOGY

Post on: 16 Март, 2015 No Comment

By LYDIA CHAVEZ

Published: December 17, 1981

In an industry noted for its grudging reluctance to embrace new technology, the McLouth Steel Corporation has long been a trendsetter.

The Detroit-based company was the first steelmaker to install the innovative basic oxygen furnace in 1954, and by the early 1970’s was the first to process all of its steel through the efficient continuous casting method. Later on, steel mills across the country were refurbished using both technologies.

Despite the quickness with which McLouth Steel embraced new technology — and perhaps because of it, some analysts say — McLouth Steel could not survive the present recession. Last week, when its 10 lenders refused to renegotiate $166 million in long-term debt, the nation’s 11th-largest steelmaker acknowledged it could not pay its bills and took shelter from its creditors under Chapter 11 of the Federal bankruptcy laws. It has 120 days to reorganize.

In part, McLouth’s misfortunes illustrate the pitfalls of investing heavily in new technology. As other American industries, notably the auto makers and airlines, have also discovered, equipment that is highly efficient at full capacity can be a financial burden when demand is slack.

Analysts said McLouth was caught with an automated and efficient process of steelmaking that became expensive to operate when its mills were not running at full capacity, was too dependent on the auto industry for its sales, and embarked on a diversification plan that was too closely tied to steel.

»They lived in the shadow of General Motors,» said Alan Kurland, an analyst with Laidlaw Adams & Peck Inc. Another analyst added, »They did well as long as the auto business did well.»

In the early 1950’s, General Motors decided it wanted another supplier in the Detroit area — at the time only Great Lakes Steel had a mill near the auto maker — and purchased $25 million in preferred stock to enable McLouth, then a finishing mill, to upgrade to produce flat rolled steel, according to William Murphy, director of public relations for McLouth. Unwritten Agreement with G.M.

Mr. Murphy said that the company had an unwritten agreement — to which G.M. adhered — that G.M. would buy a substantial part of its production. Such an agreement, Mr. Kurland said, allowed McLouth to get the financing to install the latest in steel equipment.

But no amount of new equipment could make up for a lack of orders. In fact, as orders declined in 1979, it became increasingly expensive to process steel at McLouth’s two mills.

»It put a high financial drain on the company,» said one former director with a technical background. »That kind of equipment does not take kindly to running at half speed. You just can’t scale down that easily.»

He said that the equipment made McLouth less flexible and that its operating costs spiraled as its orders ebbed. At McLouth, the drop in orders kept pace with the decline in auto sales.

While the auto industry accounts for an average of 15 percent of all steel shipments, McLouth’s sales to the depressed industry accounted for as much as 75 percent of the company’s orders and the company’s primary customer remained G.M.

»So much of what they make just doesn’t have a market right now,» said a spokesman for one of McLouth’s major lenders who asked not to be identified. McLouth was hit especially hard by an increase in domestic steel imports as well as the jump in auto imports and downscaling of Detroit’s cars. Employment Halved in 2 Years

Under normal conditions, McLouth’s employment stands at about 5,000, but during the last two years as auto sales continued to decline, it has been scaled down by 50 percent.

In addition, McLouth’s Detroit location, a plus when the auto industry was healthy, became a crucial drain when business slowed. During those periods, McLouth had to compete against the steel divisions of the auto companies to sell flat rolled steel, generally considered to have a low profit margin because of strong foreign and domestic competition.

The company did make some efforts at diversification. In the late 1970’s, it purchased the R-W Service System, a general carrier that also hauled steel. The problem with the purchase, analysts said, is that R-W is subject to a business cycle similar to McLouth’s.

How could a management with the foresight to incorporate new technology have been so overly conservative in its diversification attempt.

McLouth’s management declined to be interviewed for this article. However, analysts said that, while the management was comfortable experimenting in an industry that it knew something about, it refused to dabble in businesses that it did not know.

»They were very provincial,» Mr. Kurland said. The former director added: »They are very hard-working operating people, and they concentrated on a business that they knew something about.»

In the first nine months of this year, McLouth lost $19 million on sales of $544.4 million. Mr. Murphy declined to speculate on how the company might be reorganized, but analysts said it would be difficult since the auto market was not expected to recover until late next year.

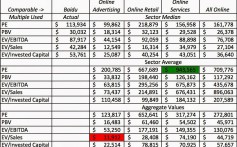

Illustrations: photo of McLouth steel plant chart