Ch Basic Features And Keys To The Development Of Production Systems In Japan

Post on: 16 Март, 2015 No Comment

SOME BASIC FEATURES AND KEYS TO THE DEVELOPMENT OF PRODUCTION SYSTEMS IN JAPAN

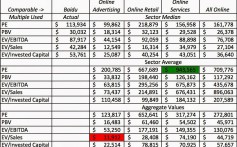

The area of product development, although a soft area in terms of technology (especially in a field such as composites), is however perhaps all the more important due to the changes in paradigm necessary for a successful completion of the product realization process. Not only does the development effort need an integrated team, but it also depends heavily on team dynamics, procedures, and even intangibles such as trust and team loyalty. In addition to technological and software based advances, developments in cultural attitudes will also play a large part in the success of this area. It is interesting to look at some data from the American Quality Foundation that compares the commitment of over 500 companies in the automotive, banking, computer, and health care industries to five strategic quality elements as in Table 7.4. For ease, numbers have been rounded to the nearest five percent.

Commitment to Five Strategic Elements of Quality

It is interesting to note that the Japanese outscore all others in three key areas: time- based competition, process simplification and performance evaluation, all of which are of critical importance to the rapid and successful completion of the product realization process. Again, it has to be understood that the development of composites will only be successful if taken from an integrated perspective which includes marketing, finance, materials, manufacturing, design, and supporting elements, all of which are already present in the Japanese keiretsu but not in the cultures of the west. While considering aspects of the PRP it is important to note that the keiretsu structure (Figure 7.16 ) allows the Japanese to be far more flexible than their Western counterparts because of ready made markets within close-knit keiretsu groups.

Figure 7.16. Structure of the Mitsui Keiretsu

In this report we will not expand on the role of the keiretsu. but will present, for the sake of completeness and understanding, the structure and interrelationships between companies within two of the keiretsu (Figure 7.17 and 7.18 ), and a schematic of the overall structure and interaction between the six major keiretsu .

These six major keiretsu are linked as shown in Figure 7.19 and coexist with a number of smaller and minor keiretsu .

Figure 7.17. The Sanwa Group

Figure 7.18. The DKB Group

Figure 7.19. Interactions Between Major Keiretsu and Other Groups

It is emphasized that this structure allows companies to speed up the PRP because of the presence of vertically and horizontally integrated teams, very often presenting both the developer, marketing arm, and customer as different companies within the same keiretsu .

In overall terms the approach to product development followed by the Japanese can be described by the following:

- The Development of a More Creative Labor Force. Almost all companies have extensive education programs led by senior managers who make a concerted attempt to pass on their knowledge to the rest of the team. In the case of companies such as Yamaha, senior managers are instrumental in putting together textbooks listing the sum total of their knowledge in the form of design rules and heuristics for the other members of the team. In the case of companies such as JAMCO, entire production lines are set up with the human element in mind. If errors occur, the individuals are educated in the appropriate technology, and simultaneously the existing production environment is investigated to determine if changes are necessary to make the best use of human capabilities. There is virtually no finger-pointing and the effort is spent on correcting the error at its source. The focus in all cases is the creation of a more creative work force, keeping in mind that people cannot be replaced by machines, even in the ultimate projection of computer- integrated manufacturing; primary human work cannot be automated.

- The Development of Global Corporate Strategy. Management strategy is aimed at long-term gains in a global market and corporate strategy is laid with those goals in mind. Investment in research consortia, joint ventures, and partnerships is encouraged and is expected to be substantial and reciprocal in nature. As part of its global strategy, Shimizu, primarily a construction and civil engineering firm, has included areas such as information systems, desert urbanization, computer hardware and software integration, and outer space development among its market aims. Established in 1804 as a construction company, Shimizu has joint ventures or subsidiaries in Sweden, Germany, France, Hong Kong, Netherlands, Malaysia, Australia, Thailand, Canada, the U.S. China, and the U.K. in areas of construction, properties, investment, and finance. It is interesting to note that unlike the major aerospace primes in the U.S. whose main business is in one market segment, the Heavy Industries companies in Japan (MHI, KHI, IHI) are more diversified, as shown by the typical breakdown of sales by percentage (Figure 7.20 ).

- The Integration of Technology with Information Systems

- The Combination of Large Leaps and Small Steps. Japanese companies are increasingly accepting that a singular breakthrough strategy is no longer adequate because it focuses R&D efforts into narrow arenas, ignoring possibilities for combining elements from different areas. Technology fusion, a term coined by Fumio Kodama, is becoming more and more apparent as companies try to combine advances in different areas in order to stay competitive in a global economy. Leading high-tech companies in Japan are following a major trend of diversification (a few examples are given in the section on case studies). The textile industry is one such example in which large R&D budgets are expended on subjects that do not relate directly to the textile or garment industry (e.g. composites in construction and building materials, as is being done by Asahi-Kasei). Toray Industries is another example where technology fusion is practiced. This company monitored the advances made by other institutions such as Union Carbide, the Royal Aircraft Establishment in the U.K. and the Japanese government research labs, and articulated the need for new products and hence material forms in both the sporting goods and aerospace areas. Extensive joint research projects are conducted in collaboration with customers, and innovative products are brought to market quickly through the adaptation of advances made in other areas to the production of carbon fiber and other products using carbon fiber.

Figure 7.20. Percentage of Sales for a Typical Japanese Heavy Industries Company (after M. Ashizawa)

Most companies aggressively pursue the search for new markets, even going as far as creating a demand for a product through aggressive demonstration projects, such as is currently being done in the infrastructure rehabilitation area. Very often the keiretsu structure is used to find the initial customers and create the acceptance. There is an increasing search for new partners with the emphasis being on increased sharing of development costs and risks, as well as the need for new ideas through technology fusion. Of late there has been a significant increase in alliances and long term agreements between Japanese and International firms; the trend is seen in the composites area as well with Tonen, Toray, JAMCO, and KHI being examples. The increase in collaborative R&D, as well as in joint ventures, is also an attempt to lock in their customer base. For further details the interested reader is referred to the excellent collection of papers in a book published by the National Research Council (1992).