Unleashing productivity The digital oil dield advantage

Post on: 16 Март, 2015 No Comment

by Andrew Steinhubl, Christopher Click, Glenn Klimchuk, and Paula Morawski

Originally published by Booz & Company: May 23, 2008

The digital oil field, an umbrella term for technology-centric solutions that allow companies to leverage limited resources, can help the oil and gas industry address its talent shortage.

This report was originally published by Booz & Company in 2008.

100,000

500,000

80,000

400,000 60,000 300,000 40,000 200,000

100,000

20,000

0 1992 1996 1993 1994 1995 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007E 2008E 2009E 2010E 2011E 2012E 2013E 2014E 2015E

F&D capex Oil consumption

Note: Does not include national oil company capex; future F&D capex extrapolated based on historical CAGR normalized for production growth. Source: John S. Herold; International Energy Agency; Strategy&

Strategy&

1. Increase manpower through effective supply-side strategies, such as more-rigorous succession planning, retention programs, proactive planning against upcoming vacant positions, focused mentoring, and marketappropriate compensation. 2. Reduce the need for increased staff by enabling fewer people to do more work and better leverage their expertise, ultimately changing the ways people are deployed to conduct their analytical work. This would entail a combination of increased automation, process redesign, and even increased outsourcing. The application of digital oil field technologies to enable productivity can be a powerful mechanism to address the demand-side pressures of unique asset portfolios and close the supply gap by accelerating employee productivity.

Exhibit 2 Employment forecast comparison

Full-time employees (thousands)

5,000 Required FTEs Constrained FTE supply

4,000

1.0 million full-time employees

3,000

2,000 2007E 2008E 2010E 2011E 2012E 2013E 2009E 2014E 2015E 1997 1999 2000 2001 2002 2003 2004 2005 1998 2006

Note: Illustrated gap of 1 million FTEs calculated by subtracting constrained FTE supply (assuming 1.5 percent annual decline) from estimated FTE requirements (assuming constant FTE/production ratio). Source: Strategy&; John S. Herold

Strategy&

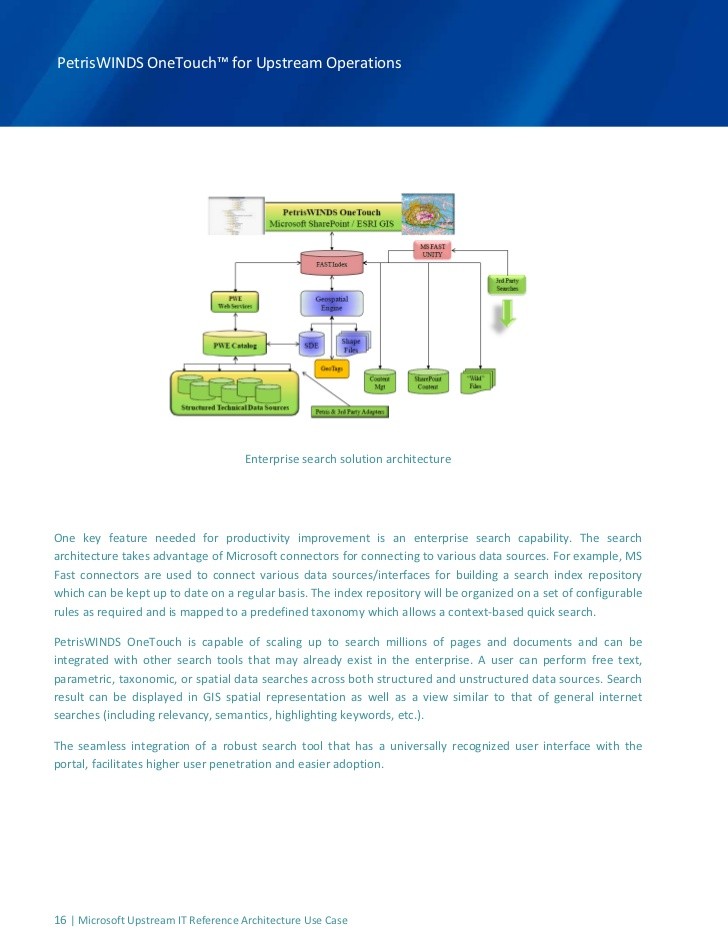

Defining the digital oil field

Digital oil field is the umbrella term for technology-centric solutions that allow companies to leverage limited resources. For instance, such technology can help employees more quickly and accurately analyze the growing volumes of data generated by increasingly sophisticated engineering technologies, such as down-hole multiphase sensors, measurement-while-drilling (MWD) applications, multilateral completions, and down-hole separation. Generally, the digital oil field encompasses both the tools and the processes surrounding data and information management across the entire suite of upstream activities. More specifically, digital oil field technologies allow companies to capture more data, with greater frequency, from all parts of the oil and gas value chain and analyze it in real or near-real time, thus optimizing reservoir, well, and facility performance. These engineering-based and information-based technologies can have a profound positive or negative impact on human capital efficiency depending on how they are introduced and embedded into the organization. A sample set of technologies that are receiving universal industry acceptance includes the following: • Remote real-time facility monitoring and control. The off-site control of facility process systems through the networking of SCADA (systems control and data analysis) and its transfer to onshore control rooms, enabling field data capture, set point control, and valve/pump manipulation. • Real-time drilling. The collection and integration of real-time drilling data such as RPM, circulation solids, downhole pressures captured through MWD, and remotely steerable down-hole tools. • Real-time production surveillance. The utilization of advanced alarm systems to trigger analysis of important production integrity trends to help optimize and maintain installed capacity levels. • Intelligent wells. Surface-controlled, down-hole equipment, enabled by fiber-optic sensors, allows for continuous monitoring of conditions and response.

6 Strategy&

• 4-D visualization and modeling. Successive 3-D seismic surveys track fluid movements, allowing for additional insight into production enhancement and redirecting enhanced recovery mechanisms. • Remote communications technology. Off-site facilities with realtime visual, voice, and data communication with the field allow more rapid, analytical responses by a mix of off-site and on-site staff. • Integrated asset models. Applications that model complete production system performance from the producing horizon, through the well-bore, through the production facility, and onto the export/ sales point across disparate data sources and multisite work teams. • Workflow and knowledge management systems. Robust historical data and document-management solutions that allow assets and functions to quickly execute workflows and routines by calling up complete historical analyses quickly and accurately. • Production volume management systems. Standardized production data and production allocations, allowing more efficient real-time production decisions that result in reduced deferment and improved operational integrity. Some industry analysis suggests improved net present value of up to approximately 25 percent from digital oil field–related implementation; from a human capital perspective, digital oil field technologies can allow companies to operate with significantly fewer resources and scale the existing resources more effectively by capturing and displaying relevant conditions more quickly and to a wider collaborative environment. For instance, one oil and gas company has quantified its productivity-based gain from introducing select digital oil field technologies at $20 million annually. It identified opportunities for direct deferment; by automating data updates and reports across a standardized master production data-store, the company removed the responsibility for routine data collection and analysis requirements from its scarce engineering talent (see Exhibit 3, next page). In other cases, the human capital benefits are less quantifiable but equally compelling. The benefit of digital oil field technologies is evident across the entire organization — from on-site at the field level, where new technologies can increase safety and reduce workload, to the management and executive levels, where staff benefit from increased transparency of information and direct daily production to the most advantageous markets. The digital oil field can even ease the competition for human resources between national oil companies (NOCs), IOCs, and oil field suppliers (OFSs). There are several drivers of such competition: For instance,

Strategy& 7

whereas IOCs had traditionally played the role of resource extractor and NOCs were resource holders, that dynamic is shifting; with NOCs better capitalized and attempting more challenging development, more skilled people are required. In another example, OFS companies had developed their capabilities around engineering and research during the 1980s and 1990s, when IOCs were undergoing significant cost reductions. As IOCs enjoy the recent boom, however, they are trying to rebuild those capabilities internally, and need the people to do so. By pooling limited resources in technologically sophisticated environments like that of the digital oil field, each of the players can leverage its strengths and cut down on the number of people needed overall.

Exhibit 3 Labor-related savings from digital oil field technology

Field data capture

Develop well status/meter change process Assign process and data owners Automate data feeds & updates Implement HH/laptops for field Build out SCADA

Monitoring & surveillance

Build well investigation process Assign process and data owners Develop optimization model (Cygnet vs. OSi) Build optimization teams Improvement initiative

Mid continent natural gas employees Reservoir engineers Production engineers Field operators Total

12 11 26 49

Field level employees responsible for initiative

0.4% or

$20 million of improved production

Value from changing existing activity sets

Process Organizational Technology

Source: Strategy&

Strategy&

Building a new operating model enabled by the digital oil field

Digital oil field technologies such as fiber-optic pressure and temperature gauges allow for sustained down-hole profiling, which offers managers more robust information and thus more comprehensive asset awareness. As information flow is directed from the field to the most relevant party off-site, this complete sense of asset awareness translates directly into asset optimization, as managers can make more informed portfolio decisions in terms of resource and capital allocation. This portfolio perspective allows the best deployment of available staff and therefore has a positive impact on the industry’s most pressing issues, offering benefits such as a reduction in production deferment due to unplanned shutdowns, higher uptime across the production system, and a reduction in health, safety, and environmental incidents. By enhancing collaboration across facilities, geographic locations, and functions, global majors have strengthened lines of communication and interrelationships between the field and office and redefined the field operating model. New collaboration technologies — such as highdensity video; reliable video, audio, and data transmission through fiber optics; and multidimensional presentation technologies (e.g. video cube walls) — have transformed companies’ ability to stay globally connected 24/7 and have aligned onshore support centers, offshore facilities and operations, vendors, partners, and non-field professionals into a collective operating unit. These collaborative environments are increasingly equipped with smarter surveillance and diagnostic tools to pinpoint relevant conditions by passing real-time data through advanced multivariable models that can be scaled across multiple assets and facilities. For instance, one supermajor has deployed a new operating model that ties together remote monitoring; real-time surveillance; and reservoir, well, and facility optimization, field planning; and work activity execution into an integrated production management center (see Exhibit 4, next page). Although early in its deployment, the operating model’s business objectives are to pay for itself and create the productivity equivalent of 19 additional engineers. To do so, it would need to reduce production deferment by a mere 0.04 percent.

Strategy& 9

Exhibit 4 Production and operational surveillance operating model

Offshore operations Operators Centralized surveillance support Surveillance technicians Asset engineering teams Well, process, facility engineers

Integrate activity plans Dynamic reporting

Determine new reservoir properties

Operate/execute production services Execute production optimization jobs

Well/subsea surveillance

Facilities surveillance

Drill & complete wells

Surveillance data management

Live feeds

Live 24×7 dashboards

Engineering team Respond to routine requests for data Management

Static feeds

Well performance Facility/topside performance

Regulatory partner

Knowledge management Issue resolution Continuous monitoring (vendor data) Historical performance Continuous monitoring (pIant) Operating guidelines

Planned vs. actual downtime Bad actor reporting Equipment availability and performance

Source: Strategy&

Strategy&

Challenges in adopting new digital oil field enabled operating models

When digital oil field technologies achieve less than their envisioned potential, it is most often because the technologies outstrip the organization’s ability to absorb them. Upstream companies face a dual challenge: first, integrating a relevant technology into existing oil field and IT infrastructures, and then working through the ripple effects of the new technology on the organizational infrastructure. In designing technology-intensive value chains for the digital oil field, companies must consider common business challenges and elements of organizational complexity, from conditions to process to implementation (see Exhibit 6, page 15). Implementing the digital oil field will have a definite impact on the organization at the field, management, and executive levels. Explicit and tacit role definitions, skill sets required for successful fulfillment of particular staff positions, and organizational enablers such as decision rights will all change, and this organizational change must be effectively managed. Field level: The key issue in implementing the digital oil field at this level of the organization is a limited degree of acceptance from operating personnel. The major hurdles to adopting the technology include: • Lack of willingness to accept significant organizational change and adjust work practices • Technology that is not “fit for purpose” and does not meet the local work requirements • Staff that is not involved in establishing functional and systems requirements nor in vendor selection • Not allowing staff time away from their normal activities to work on technology implementations (potentially solved through contractors)

Strategy&

• Lack of dedicated internal champions • Inadequate training to prepare and support them in using the new tools effectively Management level: The key issue here is that siloed work environments must be broken down to allow for communication and interchanging roles across disparate operating groups. The hurdles are: • Ineffective resource allocation across projects and other initiatives • Lack of role definition and alignment of decision rights as off-site, on-site, and service company employees are integrated into a new interlocking model • Embedded skill sets that don’t grow in tandem with the adoption of digital oil field tools and applications, with more time spent analyzing larger portfolios of reservoirs • Gain-sharing agreements not established with service providers Executive level: Finally, at the executive level, we see three issues: a lack of top-down encouragement, a failure to make a compelling case for technology adoption, and an unfavorable environment to risk taking. The challenges to technology adoption include: • Not having the resources, both capital and staff, to support the transition • Implementation that is not coordinated across far-flung global enterprises • Strategic value proposition that is ineffectively communicated in terms of total system value, resulting in limited buy-in • Short-term operating targets that are not adjusted

Strategy&

Exhibit 6 Reconciling technology and organization

Adoption success requires managing across three elements of complexity

Conditions Determining asset requirements Leveraging technology Asset complexity Functional requirements Technology requirements Established architectures Existing investments Off-the-shelf vs. custom development Integration vs. best of breed Ensuring process Process ownership effectiveness Replication/standardization Simplification Ensuring people User ease and utility effectiveness Roles and responsibilities Training Ensuring data integrity Automation Traceability Data ownership Data models Culture and behaviors Decision rights Outsourcing effect Communication Management reporting Revenue accounting Process Plan production volumes and capacities FDC and measurement Production forecast Marketing opportunity capture Well stock Real-time data collection Manual and automated alarming and intervention Implementation Established vision Leadership and stakeholder acceptance Business case/ justification Future state defined Mutual understanding Executive involvement Business units gatekeeper

Deferment reduction Intervention improvement Labor effectiveness

Production Daily performance reporting Optimization and surveillance Deferment management Production allocation and accounting Zonal performance Net performance Allocations NRI/GWI accounting Gas plant, P/L accounting Price application Contractual management Nomination management 3rd party accounting Price application Contractual/PSC Marketing arrangements State/fed reporting Partner reporting Operations and management reporting

Project management and vendor alignment Functional and systems requirements Implementation strategy and road map

Global coordination BU program execution Strategic partner Risk management BU basis Asset complexity IT infrastructure BU resourcing Plan robustness

Key considerations • Global vision • Business case articulated to senior management • Standard process models • Well defined functional and system requirements • BU/corporate alignment • Internal project and implementation management capability

Source: Strategy&

Strategy&

Keys to successful implementation of new operating models

Proving the maxim that technology cannot be a solution in and of itself but only an enabler of enhanced performance, two major organizational levers predict digital oil field success: capability development and organizational alignment. Capability development: Building an organization’s capabilities by harnessing and disseminating knowledge effectively is a critical requirement for digital oil field success. Previous reductions of oil field head counts and more recent retirement-based reductions open up the possibility that tacit knowledge, experiences, relationships, and solutions will be lost, as low-value tasks are automated and real-time data is gathered and transmitted. Despite recent investment in knowledge management systems, today’s modern oil and gas companies continue to struggle to find effective ways to transfer their inherent knowledge capital between teams, between generations of employees, between subject matter experts, and across functional and reporting layers. Developing a knowledgesharing mind-set entails a significant commitment to training people and developing a distributed learning infrastructure in which lessons learned and previous engineering work are documented, accessible, and quickly distributed to deliver maximum value. Employees at every level of the organization need to be taught and motivated to recognize opportunities to institutionalize knowledge and learning. As such, field, divisional, and personal performance contracts must be adjusted to align organizations with this inevitable operating condition. In the operating environment enabled by the digital oil field, staff must have the skills to interpret complex data models, as well as the ability to manage a more dynamic work environment in which production parameters are altered daily instead of weekly or monthly to leverage the value of more accurate and comprehensive real-time data. Developing training simulations that model real-world operating scenarios represents a powerful medium to ensure adequate operating level employee skills. As part of this learning process, digital oil field environments can be simulated so that newly aligned staff must operate under a set of new procedures and business rules and respond to

16 Strategy&

designed scenarios. Such scenariobased simulations allow the organization to test alternatives and highlight issues of staff proficiency and organizational inefficiency. At the management level, skill and capability gaps can be closed more quickly by leveraging knowledge across previously autonomous operating units. Accordingly, scarce resources and expertise can be most effectively deployed through collaboration centers that allow for fluid skill and document transfer across disparate functions and assets utilizing automated workflows. Locally based collaboration centers such as drilling, remote monitoring, system surveillance, and production optimization in conjunction with global “centers of excellence” (COEs) provide deep yet scaled knowledgebased organizational levers that aggregate and standardize processes and skills at the appropriate levels in the organization while better concentrating and deploying scarce subject-matter expertise. By generating both local and enterprise-wide knowledge, these centers concentrate knowledge, ensure consistent transfer of skills, monitor functional delivery, and ensure continuous communication with asset, operational, and functional stakeholder groups. The focus of these COEs can be on any of the elements of a new capability, operating model, or major technology being implemented: For instance, one oil and gas company’s production management center implementation has combined processes for the documentation of asset requirements, risk assessment, best practices, and existing protocols with program management office functions to plan for and implement technology solutions (see Exhibit 7, next page). These COEs help reduce digital oil field–related adoption risk by stewarding and testing new technologies, building training programs that accelerate organizational adoption, and leveraging project management knowledge to ensure budgets and schedules are met. Aligning the organization The ability of a company, a business unit, or a team to execute a strategy is not something that can be mandated by fiat. It is inherent in the organization’s DNA and expressed in the hundreds of decisions and actions that collectively constitute and define performance. Would-be digital oil field operators can, however, attempt to align the building blocks of a company’s DNA — decision rights, information flows, organizational structure, and motivators — to better capture the digital oil field’s benefits. In order to realize the full potential of digital oil field technologies, organizations must be aligned and interrelationships established — for instance, between engineering functions, assets, and functional reporting relationships through an integrated set of key performance indicators (KPIs) (see Exhibit 8, page 19). A significant part

Strategy& 17

Exhibit 7 Program management center of excellence

Major elements of the program management centers of excellence operating model

Vision and purpose

Vision, objectives, and purpose Purpose and scope Define support model Define sub-programs and components Information system plan Guiding council Technology leader Functional leadership Tech services leadership Manage governance model Program office Project manager Potentially permanent BU project managers role in COE Staff requirements Vendor manager Project planning Project initiation documentation (PID) Asset tracking Covers scope, deliverables, benefits, milestones, risks, dependencies Associated economic-based analysis Progress reporting Weekly program meeting Monthly board meeting Risk assessments Risk number Clear description Baseline likelihood assessment Monthly residual risk assessment Value impact Graphical presentation

Documentation and control

Asset requirements Wells — Rate and phase — Operating guidelines Facilities — Compression performance — Rotating equipment integrity Subsea — Flow line assurance — Pod integrity Processing system — System pressure Export system — Pipeline control Knowledge capture Team and subject matter experts Project status and needs Best practices Application database

Implementation management

Program office meeting Directing or guiding Implementing vs. advising Information system plan adjustment Process model definition Change control Issues log Scope creep tracking Functional gaps Expenditure or benefit tracking Technical model definition Project closure Benefit measurement Initiative description Key learnings Close out authorization Change management Training User communication Job descriptions RACI development Automation Infrastructure Telecommunications Application Workflow Information flow Data model Roles and responsibilities

Source: Strategy&

Strategy&

Exhibit 8 Examples of digital oil field operating model KPIs

Type (outcome, output, activity) Data source a. SharePoint workflow b. SharePoint workflow Stakeholder (to whom is it reported out?) Frequency of reporting Data owner (who owns this data?) – IT/surveillance systems technician

Objectives Objective 1: Off-load engineers to facilitate identification of high-value optimization opportunities Objective 2: Conduct surveillance services to reduce decision cycle time for engineers

Measure

a. Number of engineers a. Activity using services b. Output (workflow completed) b. Number of times services executed a. Percentage of services completed within schedule a. Outcome

– Surveillance managers/production – Monthly surveillance manager – Quarterly – PLT

a. SharePoint workflow

– Surveillance managers/production – Monthly surveillance manager – Quarterly – PLT

– IT/surveillance systems technician

Objective 3: a. Percentage of Extend scope and ad hoc requests coverage of high-priority for surveillance services surveillance activities

a. Activity

a. SharePoint workflow

– Surveillance managers/production – Monthly surveillance manager – Quarterly – PLT

– IT/surveillance systems technician

Source: Strategy&

Strategy&

of organizational alignment will involve creating new roles, redesigning existing processes, and aligning performance measures to support and execute collaborative working conditions. In addition to aligned operating model KPIs, the process of creating new roles must begin with a robust analysis of labor supply and demand dynamics, in which present and future capability gaps are clearly understood. The supply analysis provides insight into potential areas of concern, such as high turnover, recruitment constraints, and the impact of retirement eligibility on the company’s ability to effectively utilize technology solutions. The demand analysis provides a baseline understanding of how work is distributed across the organization and how the current levels of staffing and competencies are used to perform work. It also yields an understanding of anticipated changes in the nature, type, and quantity of the work, including changes resulting from the new business process flows and technology introductions. Formal capability development associated with integrating new digital oil field–related skills should be an integral part of today’s oil company staffing models and must inherently consider the degree of changing work task complexity, technology adoption, and skill transfer timing requirements. Exhibit 9, next page, shows a high-level two-year handoff plan associated with transferring lowercomplexity tasks from surveillance engineers to surveillance technicians within a newly established production operating center. The complexity associated with various tasks should similarly guide resource allocation models and hiring plans to determine the adequate number and type of staff needed for digital oil field enabled environments. Analysis of the time associated with completing tasks of varying complexity can be used to derive staffing estimates, both as production is starting up and once it enters a steady state (see Exhibit 10, page 22). The staffing model similarly represents a key complement to the labor supply and demand analysis discussed previously.

Exhibit 9 Two-year handoff plans