Six Sigma

Post on: 16 Март, 2015 No Comment

Since Lean and Six Sigma are so complimentary and are becoming so commonly used together by professionals in modern process improvement methods I reference the following description when describing both Lean and Six Sigma.

Lean-six sigma is a fact based, data-driven philosophy of improvement that values defect prevention over defect detection. It drives customer satisfaction and bottom-line results by reducing variation, waste, and cycle time, while promoting the use of work standardization and flow, thereby creating a competitive advantage. It applies anywhere variation and waste exists, and every employee should be involved.

American Society for Quality endorsed “The Certified Six Sigma Black Belt Handbook”

While Lean focuses on optimizing flow, eliminating waste, decreasing employee frustration, decreasing customer lead-times, and decreasing costs, six sigma corrects business systems and processes that cause errors with a particular emphasis on errors directly affecting customers.

Six sigma as it originated in the manufacturing environment is a method that helps organizations reduce defects and variability in product specifications so that customers experience close to zero defects. As succinctly described in Wikipedia: “In Six Sigma, a defect is defined as any process output that does not meet customer specifications, or that could lead to creating an output that does not meet customer specifications”. The term sigma level refers to how many opportunities exist in aggregate for all the individual discrete elements in a process not to function as intended causing, or potentially causing, a defect. The calculation of “six” sigma translates into 3.4 defects a process produces per million opportunities.

Six sigma process improvement in services rarely attempts to decrease defects to the true six sigma level. Such defined specifications and data usually do not exist in services to calculate a sigma level. In services six sigma refers to a project management methodology that relies on the effective management and on-the-job education of a chartered team. The team should consist of the people at the “Gemba”. This is the Japanese term for where the work is being done. Staff that either have inputs into the process, are involved with executing the process or recipients of the process output need to come to consensus of exactly how the process works from beginning to end and have input in improving it.

Organizations that choose to adopt primarily a six sigma approach to business improvement, usually larger businesses, are recommended rules of thumb for a six sigma infrastructure. This requires putting into place staff trained and designated master black belts, black belts, and green belts and sometimes yellow belts. There are further facilitative roles such as executive champions and process owners.

The idea is to have a minimum threshold of trained experts to gain and sustain momentum in achieving business results increasing business capacity and reducing defects often worth millions annually. For large organizations with thousands of employees this may be an effective approach; certainly successful high profile examples like GE and Motorola are often cited as evidence. However, as in every business endeavor requiring disruption of organizational habits, its not the theoretical concepts and rules of thumb that improve the organization but the skills, attitude, and behavior of people to execute concepts and tools to achieve well understood objectives.

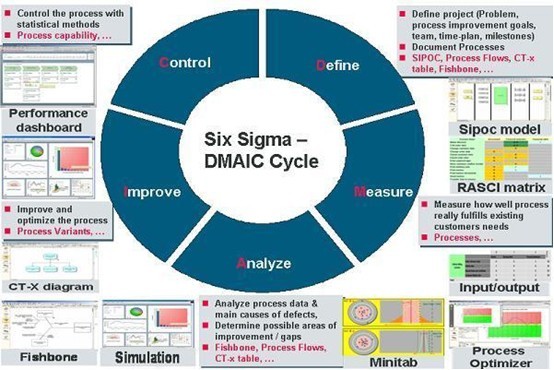

Six sigma offers guidance of phases. Each phase is supported by associated tools, to make gathering and analyzing data easier. This in turn makes teams more likely to succeed in quantifiably decreasing defects and sustaining improvements. Therefore no rigid rules should dictate infrastructure. Ultimately organizations don’t want to be in the all too common condition of not being able “to see the forest through the trees”.

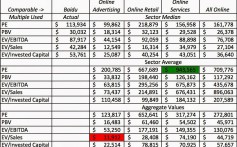

My personal experience in multiple industries over decades of improving operations is that most improvements get hung up in the initial stage on very succinctly defining the problem requiring a solution. This blurs the very specific objective of what the teams are chartered to do. Having a very precisely defined problem and team objective reduces frustration and greatly increases the probability of realizing a return on investment from mobilizing the team. The next stage teams get hung up on is honing in on what information to collect and how to analyze it to find the “true” root cause. This is where the six sigma methodology (referred to as DMAIC) can effectively guide teams to achieve fact based “quantifiable” improvements to customer needs and the bottom line. The table below is a summary of the phases.

In services, often the relatively simple concepts and statistics suffice to succeed in improving the way businesses perform. Within a couple of projects the usefulness and benefits of the methodology become practical.

Recently, service industries including banks, insurance companies, retail establishments (including big box retailers such as Wal-Mart), hotels, restaurants, insurance companies, airlines, and many others particularly healthcare are gaining competitive advantage through the creation of continuous business improvement. In the hyper-competitive and challenging economic environment satisfying customers, investors and other stakeholders requires organizational innovation. Innovation can only come from the motivation, encouragement and engagement of people. It is the critical investment often overlooked and under appreciated.

Today’s reality is that businesses need people to continually improve. People cannot stand still or improve slowly. Unless people are improving constantly, businesses are falling behind their competitors who are training and motivating their people to improve faster. Bringing an organization through a Lean Six Sigma business improvement transformation elevates senior leaders and managers to continuous turnaround professionals who become more valuable to their organization or any other organization they may lead in the future.

No business can stand still: if your not continuously improving youre falling behind.

Speed up your competitive learning curve:

Call Stephen Halikas to work with senior teams, middle managers, and front line staff in business improvement to better serve customers while lower operating costs by eliminating waste and mistakes to increase your profitability.